Tried, Tested, & Proven

Reliable.

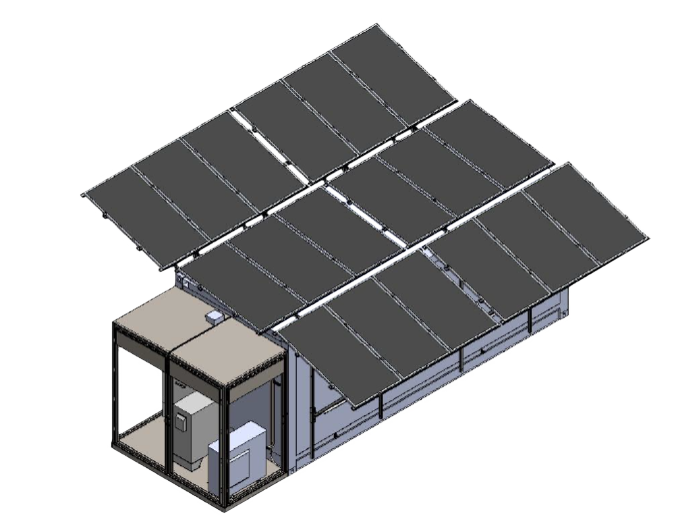

SPCS Unit

(Solar Powered Cold Storage)

SPCS units are walk-in coolers and freezers that operate reliably off-grid to provide rapidly deployable solutions for a wide-range of cold-storage applications.

State-of-the-Art

Technology

Our units employ a split refrigeration system that uses the vapor compression cycle with an external condenser for heat rejection from the cold storage space to the ambient.

The condensing units utilize highly efficient, quiet compressors that are sized to run cyclically even on hottest summer days to maintain cold-space temperatures between user-specified limits.

Our units implement refrigerants that meet new and forthcoming standards on global warming potential. This will enable our customers to sustain operation as the refrigeration industry moves during this transition period to the new family of refrigerants that provide lower effective carbon footprints.

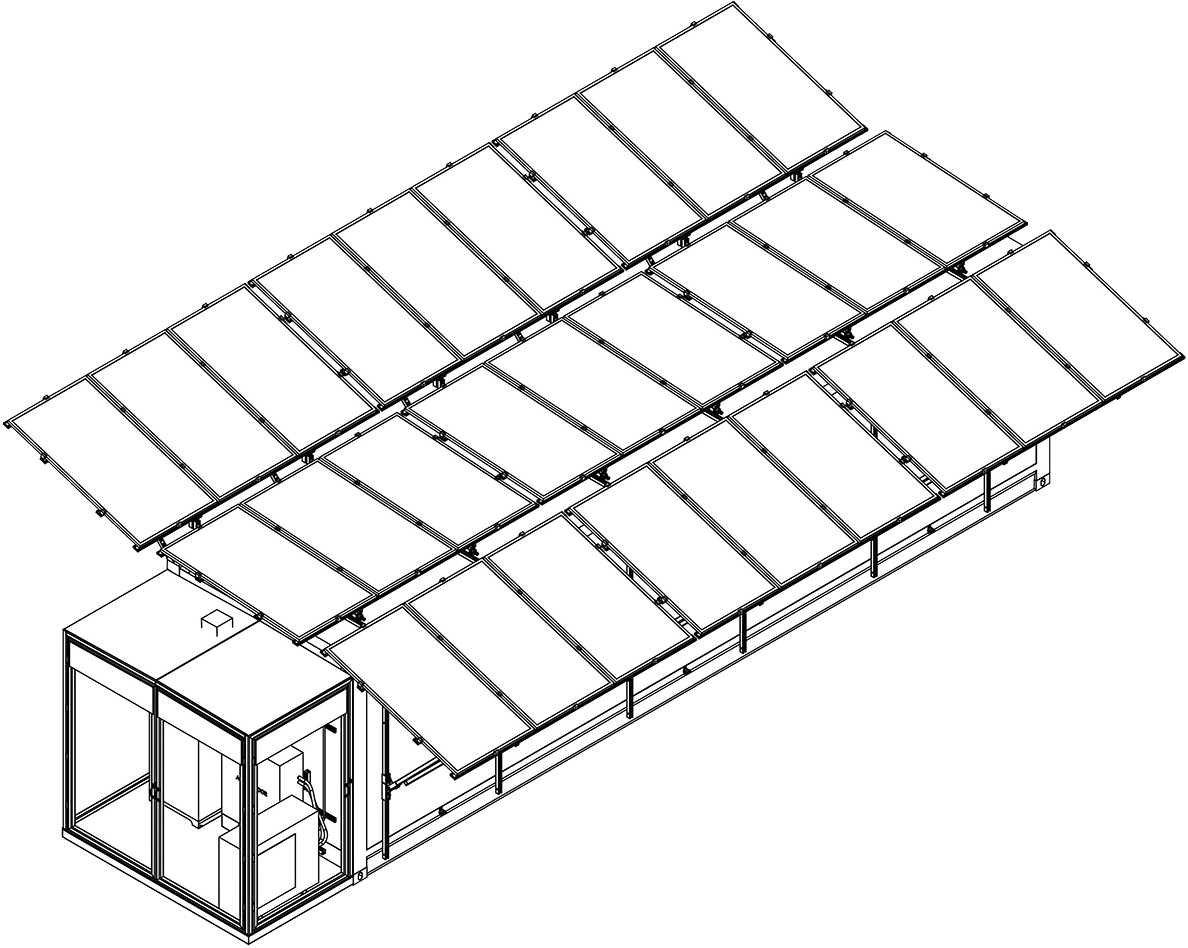

To facilitate reliable off-grid, operation, we focus on solar panels that have high efficiency (above 21%) and utilize PV panel architectures that provide good low-light performance.

These panels are deployed in multiple panel strings on the roof and canopy off both sides of the container to provide adequate solar power for the refrigeration system and for recharging the batteries even on days with less than perfect solar insolation.

With manually adjustable angles for the canopied panels, our systems can be quickly adjusted between four settings to increase solar power production throughout the yearly cycle.

Our units rely on LiFeP04 batteries for energy storage both overnight and throughout days with poor solar energy collection.

Each battery module has a fully integrated battery management system (BMS) that regulates the cells and ensures that they are within safe operating conditions.

Each battery pack is comprised of battery modules. The battery pack for each unit is sized based on the unique energy needs of each location. In-house models and simulations help us properly size each battery pack.

A critical component of reliable off-grid operation are the power electronics that includes:

1 – The solar-charge controller that converts the high voltage of the PV panel strings to the appropriate battery voltage and

2 – The power inverter that converts the battery voltage to AC electrical power for supporting the large AC loads associated with the refrigeration system.

Our units utilize an all-in-one power electronics package from a leading supplier in the solar, off-grid power electronics space. The solar charge controller supports high voltage panel strings for reducing costs and provides reliable utilization of excess solar power when the batteries are fully charged. The power electronics package works well for freezer units as large as 40 ft. Remote monitoring of the power electronics enables users to assess system performance remotely and rapidly.

We ensure that all of the major components are outfitted with appropriate controls to provide information remotely through a cellular modem to the cloud.

Our partner Wattch.io provides computational cloud services to host the data for users and provides some basic remote controls. Key performance metrics such as battery state-of-charge, PV power output, and AC power draws are tracked and monitored remotely, to inform controls for the refrigeration loads and battery charging parameters. Our units can be managed remotely in order to ensure reliable off-grid operation.

Other instrumentation including a cold-space gas sensor provides information for informing ventilation systems and monitoring food quality for applications involving the storage of fresh, local produce.

Through internal research and support from the USDA, Radiant is completing the roll-out of our unique model-predictive control software (patent pending) that will allow users to purchase a cloud-based computer control to ensure reliable off-grid operation of the unit even through periods of limited solar insolation over several days.

The cloud-based control software relies on the thermal energy models of the SPF units and dynamic weather forecasting to manipulate power loads to maintain adequate battery state-of-charge through forecasted weather events.

This software can be offered as a service for users to implement to combine remote monitoring with the model-predictive controls for off-grid reliability.

Effective unit design for

Rapid Deployment.

Get to know our solar-powered

Coolers/Freezers

SPCS

Ordering Process

One Day to One Week

Initial Inquiry

Client provides information about the objective i.e., project, location, requirements, limitations, budget, etc.

Two to Three Weeks

Scoping

Radiant conducts a site visit and further defines need re: permitting, site prep, workflow considerations, etc.

One to Three Weeks

Design

Radiant provides design recommendations.

Four Months

Production

Client places an order, signs a purchase agreement and pays down payment. Production process commences.

One Week

Placement

Radiant delivers the product and ensures start up performance

Up to Twelve Months

Monitoring

Radiant provides remote performance monitoring.